Curling | How to stop the knit fabric from curling

Curling is one of the primary futures of a single jersey knit fabric. Whenever you see any single jersey fabric it has open ends and you will always observe that the fabric is curling from the edges. When you cut the woven fabric the fabric remains stable on the surface and knitted single jersey fabric when you will cut it from any side from the edges it will try to curl, it will try to bend and it will never remain stationary like a flat surface

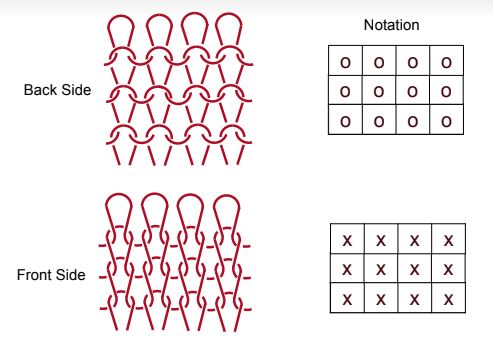

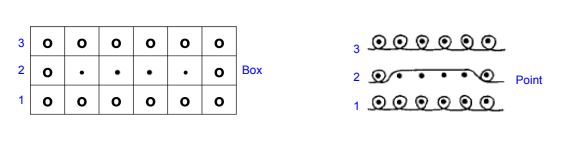

Along the whale line, the nature of curling will be completely different. So the fabric is trying to curl from the technical front to back side. The fabric is bending from the technical front to the back side all the loops which are present on the left side of the fabric are bending towards the backside.It has different nature along different surfaces. Free ends on the wale line, if you see the edges the nature of the curling will be completely different. The fabric will try to curl from the technical front to the back side.

If you observe along the course direction all the top loops are trying to bend towards the front side. So along the edges, the fabric it is bending towards the back but on the perpendicular side it has the opposite nature, it is bending towards front side

whenever you create a loop with the yarn, it is either coming out from the old loop or either it is going inside the old loop. So in this process, you can see the yarn which is there inside the loop.

Reason for knit fabric curling

The yarn part of particular loops is always in the bend position. if you see any textile yarn it is always in straight conditions, but when you make this yarn bend into the same unstable position, naturally the yarn will try to relax. Whenever we are creating the loops the yarn loops are in a bent state, it is highly unstable, all yarns are in a strait configuration, but inside the particular fabric we are forcing this yarn to bend in a certain fashion to create the loop, so this bending state is highly unstable, And once any object is in highly unstable state naturally it will automatically try to move into a stable state because this kind of configuration is not supported by the law of physics itself. So naturally the yarn which is not supposed to stand in a bent state, has always the tendency to go back to its original state.

And what is the original state? Which is the straight configuration. You can also understand by a simple example, let’s suppose we take any rod from a side if you bend it and if the road is elastic, the movement you release the force it will always try to go back to its original state configuration

because of the unstable behavior of the single jersey fabric ends become highly unstab

How to avoid fabric curling

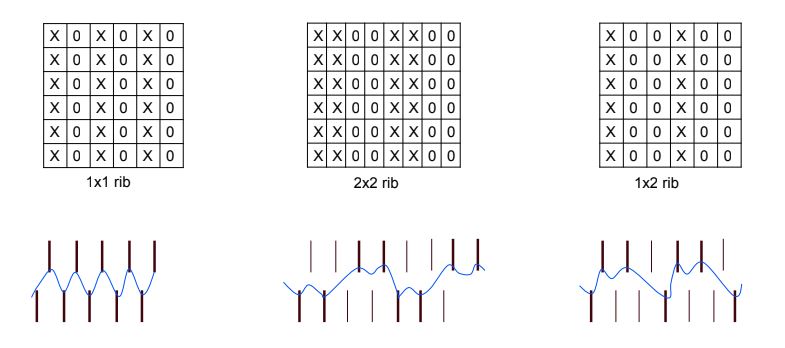

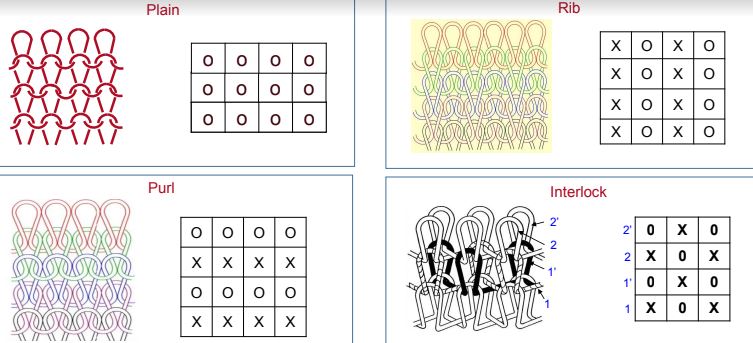

To avoid fabric curling we have another category of fabric in knitting which is called double jersey fabric. Double jersey fabric is formed by 2 sets of needles, beauty of this fabric is it does not curl from any side both side has both front and back loops.

A fabric that is produced on the double bed knitting machine is called double jersey fabric. Double jersey fabric does not curl. Due to technical face or back loops on the surface, the net resulting torque is nullified along course and wale.

If you see the sweater design mostly the collar, neck, and bottom segments are made from double jersey fabric to make the structure stable. For creating more stable fabric need to use a double bed machine, especially v bed knitting machine

to avoid curling we need to produce double jersey fabric which does not curl from the edges