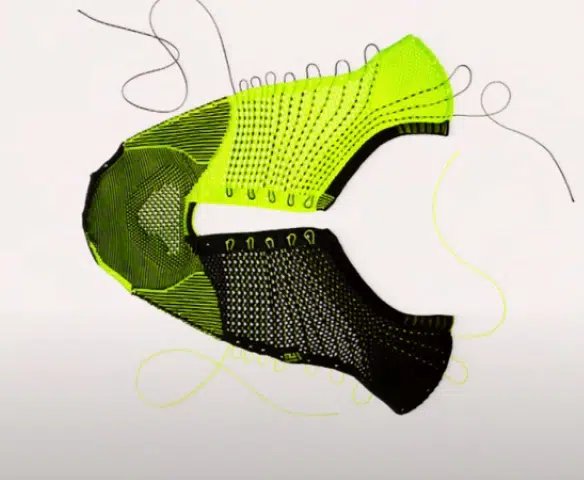

Knit Shoes are trendy nowadays, different kinds of attractive structures are now used to make knit shoes. Mostly using weft as well as warp knit structures. Apart from shoe uppers, manufacturers are making completely sockless shoes made up of knit structures. And the beauty of knitting is, not only you can make the product but also you can create a very beautiful surface design on the product, so that’s why knit become very popular

For controlling the fabric properties for these shoe structures using hot melt yarn. By using hot melt yarn we can create a less extensible fabric, especially on the jacquard knitting machine. And also we can create it on a warp knitting machine

Hot melt Yarn process for making Knit Shoe

Hot melt yarn is fused with the normal filament like polyester or nylon or PP. Usually use hot melt PET which has the lower melting point, 110 degrees; or hot melt PP ( polypropylene ) which has around melting of 60 degrees celsius. And combine this filament with higher temperature polyester which is around 260 degrees celsius. After fusing these two types of filaments and creating a fabric structure. After melting the hot melting yarn the loops get locked, hence the extensibility of the fabric structure will become control